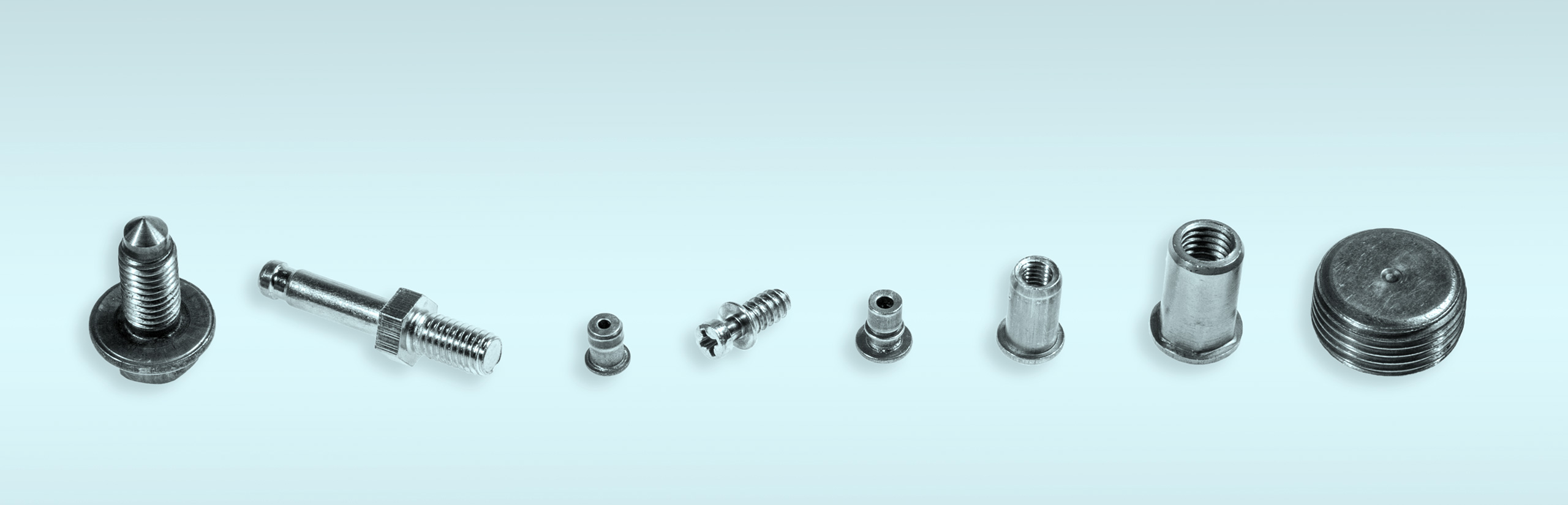

Many Years of Experience

The many years of experience of our mashine setters enable them to go to the limits of what is technically feasible. Furthermore, we achieve a constantly high quality and turn a good production process into an even better one.

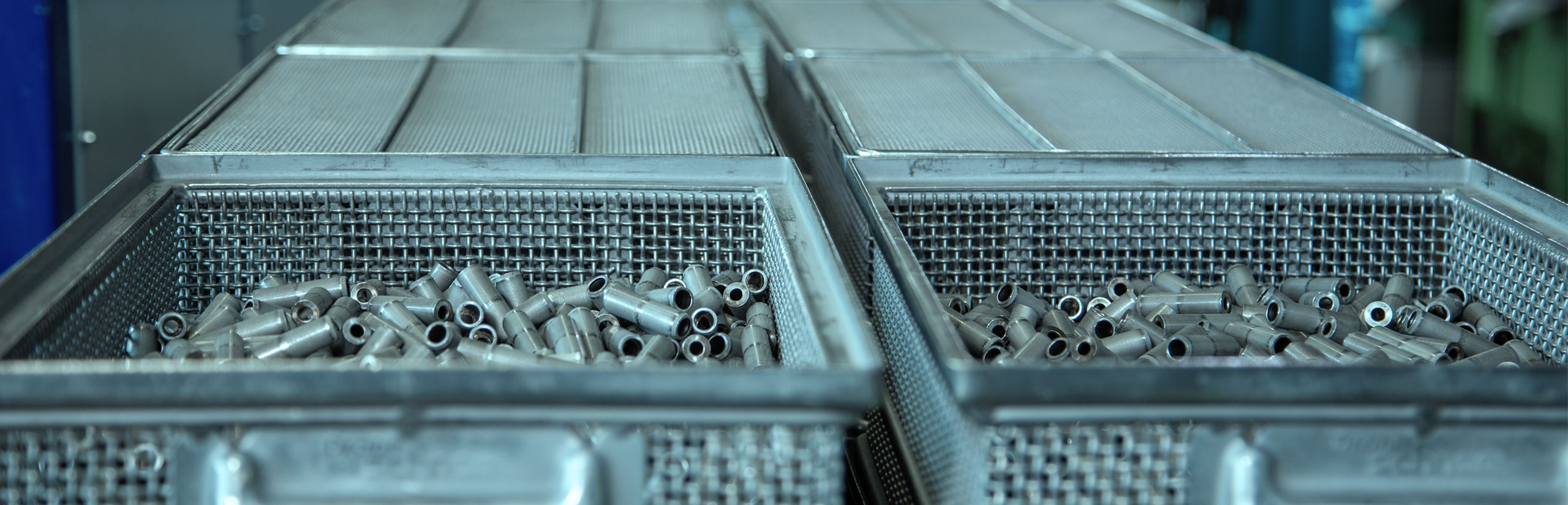

Specialisation in large Series

Lean production and flat hierarchies make us an ideal partner especially for large-volume orders. Our customer benefits from a favourable cost structure, short decision making processes and thus a high degree of flexibility.

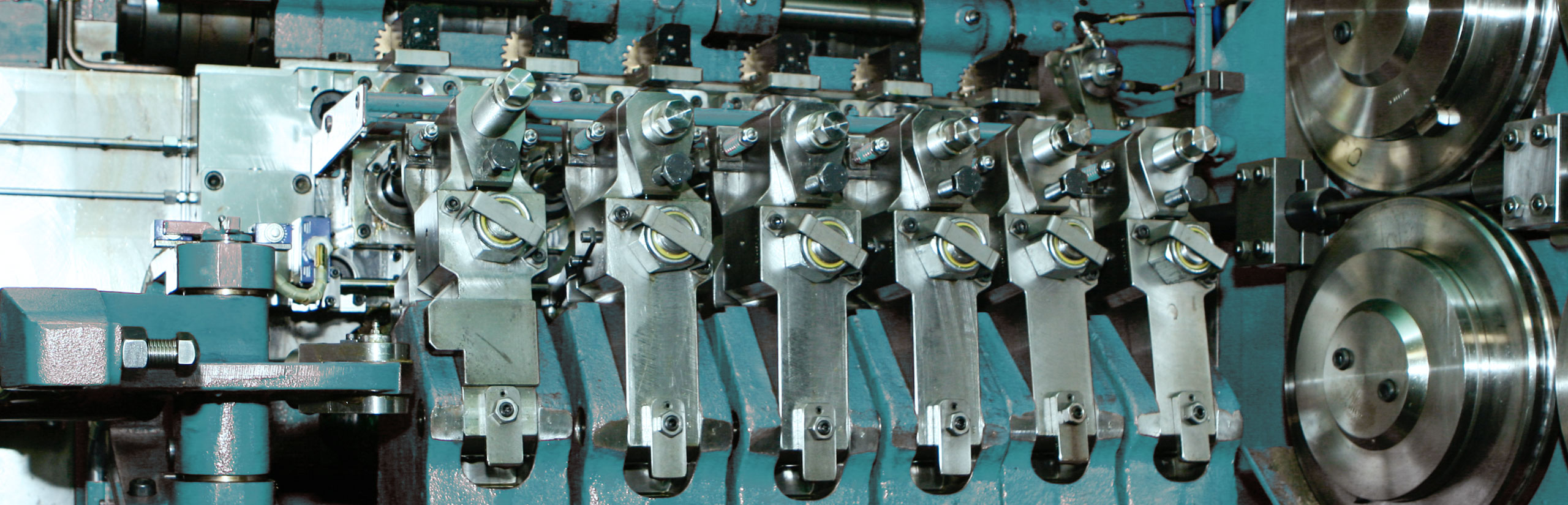

Flexibility through plenty Machinery

The choice of suitable multi-stage presses for specific projects enables an optimised and most cost-effective manufacturing of your products. Whether short or long parts, light or heavy, with simple or complex geometries – we find the right way.